Tire Education

What are the

strengths of all-steel radial

tires?

As we all know, radial tyres have been widely used in automobiles and motorcycles with key features to ensure user's travel safety.

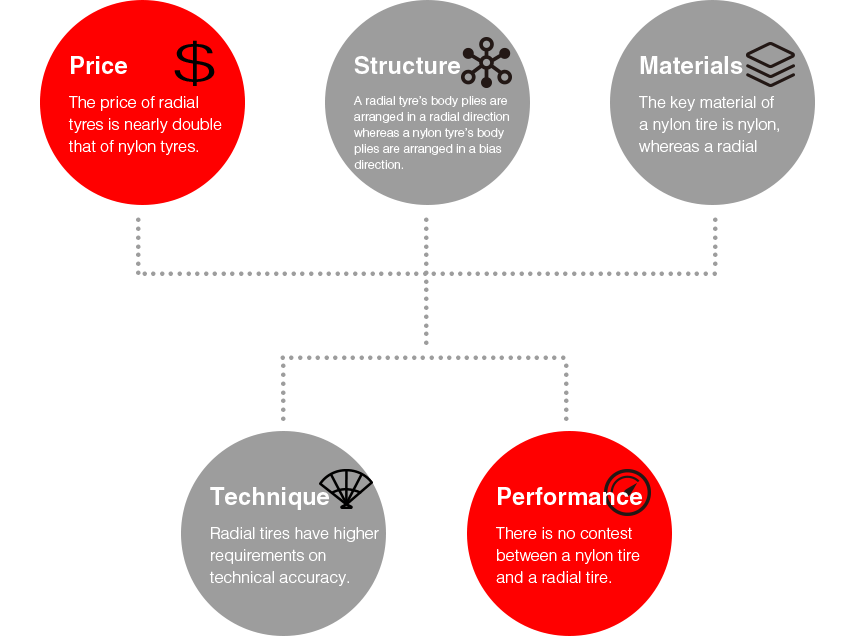

The difference between radial tires and nylon tubeless tires

Energy Saving: Due to the less tire plies, radial tires feature low heat generation and fast heat dissipation. The small deformation of carcass reduces the rolling resistance by 15%-20% than that of ordinary diagonal tires, and the rolling distance is about 25% longer. This tyre not only can increase the speed, but save much more energy.

Durability: There is a rigid belt layer between the tread and the carcass ply. When a radial tyre rolls on the road surface, the carcass deformation is small, which makes the relative slip small. Because of the large radial elasticity of the tyre body, the ground contact area of the tire is increased and the pressure is reduced, so that the tread wear resistance is stronger and you are unlikely to have a flat tire. The mileage can be 30% higher than that of ordinary diagonal tires.

Easy to Repair: After being repaired, the network of steel cords in a radial tyre forms an iron fence to prevent the rubber strip from shifting and falling off when riding, whereas the nylon tyre material has insufficient strength so that the rubber strip is easy to fall off.

Puncture Resistance: The radial tyre carcass is made of ultra-high-strength steel cord, whose tensile strength is about 20% higher than that of nylon cord. Therefore, under the same density, the radial tire is more puncture resistant.

In addition to the four key features, because radial tires lay all of the cord plies at 90 degrees to the direction of travel, the strength of the cord is fully and effectively utilized and the load capacity of the radial tire is 10% higher than that of the diagonal tyre. In conclusion, radial tires have very good overall performance in all aspects.

What are the

truck tire maintenance tips?

Regularly rotation of the tires, selection of appropriate tread patterns, daily maintenance, regular inspection of tire pressure, timely repairs after damage, and remove stones and foreign objects stuck in the tire treads are all important tips to extend the life of the tire. After the tires have been used for a period of time, factors such as the camber of the road surface, the brakes and the different assembly positions of the tires can greatly affect the tread wear. The tires should be rotated regularly to distribute the tread wear evenly and help them last longer.

Follow the recommended air pressure and ensure that the tire pressure is at the standard value. Overinflated or underinflated tire will have more wear and less mileage. When the tire pressure is lower than the standard, tire shoulder wear will increase sharply. When the tire pressure is above the standard, the ground contact area becomes less, the middle of the tire tread wears faster, the rigidity of the tire becomes bigger, so that the dynamic load on the wheel increases, which can easily result in tire blowout. The impact can be even worse when riding on uneven roads or at high speeds.

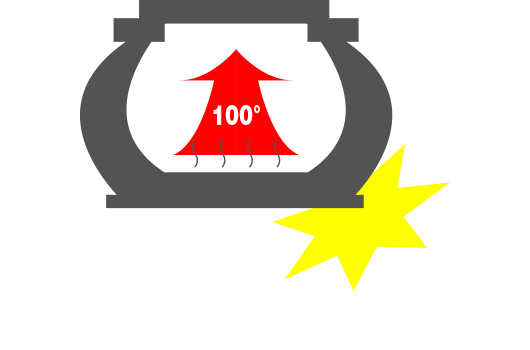

When a car is running, the tire temperature rises due to deformation and friction. When it reaches above 100°C, the strength of the carcass is greatly reduced, which can easily result in damages such as delamination and blowout. Tire temperature can not be easily measured. We usually judge the temperature by the degree of tire pressure. The higher the tire pressure, the higher the tire temperature. When the ambient temperature is above 30°C, the increase in tire pressure should not exceed 20% of the inflation standard. Du to poor heat dissipation conditions, the tire temperature may easily exceed 100°C. When driving in hot in summer, if the tire temperature is too high, you should park in a cool place to cool it down naturally. Pouring cold water on tires will make the tire cool suddenly, whereby different parts will shrink unevenly to cause tire cracks that reduce the tyre life.